Standard Cabinet Type Blasting Machines

Product Details:

Standard Cabinet Type Blasting Machines Price And Quantity

- 1 Nautical Mile

Standard Cabinet Type Blasting Machines Trade Information

- 10 Nautical Mile Per Week

- 3-4days Days

Product Description

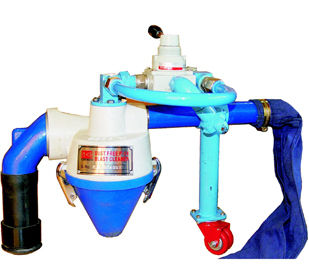

Owing to our market expertise, we are engrossed in offering an extensive range of Standard Cabinet Type Blasting Machines. This machine is fabricated by utilizing premium quality components and latest technology as per the set industry norms. The offered machine is recognized to smooth the surface of any metal, shape a surface, remove surface contaminants, etc. This Standard Cabinet Type Blasting Machines is available in various specifications to meet the specific needs of the clients.

For the best standard cabinet type blasting type, purchase the model offered by us. The MEC cabinet type abrasive blasting machine is environment friendly and is suitable to generate anchor patterns on various components. This process can be carried out in a cabinet enclosure, where the operator will use the hand holes to maneuver the blasting nozzle available at the front side of the cabinet. Also, a vision window is present on the front of cabinet to see the blasting operation.

Standard Cabinet Type Blasting Machines are available in 3 variants viz Pressure Blasting, Suction Blasting & Wet Blasting. These are explained below:

- Suction Blasting: It works on the principle of Injection Suction Blasting. It also implements the venturi principle for drawing abrasive from a hopper which is non-pressurized to the blast gun, wherein it gets mixed with compressed air stream and thereafter is propelled against the work surface. The suction blasting machine (cabinet type) has two hoses (one each for abrasive & air) which run through the blast gun.

- Pressure Blasting: It works on the principle of Direct Pressure Blasting and uses "blast pot" or a pressurized vessel for holding the abrasive media. In this machine, the air pressure in "pusher" line and vessel is same. This directly implies "Zero Pressure Differential" between the blast line and blast pot. Owing to this, the abrasive media meters into air stream at pot from where it runs through the length of blast hose to the nozzle. This equipment has one hose which runs to the blast nozzle.

- Wet Blasting: This machines works on the principle of Injection Suction Blasting. It has a slurry pump which is for drawing wet slurry of finest abrasive, water to the blast gun. Here, it gets mixed with compressed air stream and thereafter is propelled against the work surface.

Features:

- Long servicing life, high strength and automotive

- Trouble free performance with low maintenance cost

- Robust construction, easy to clean and energy efficient

- Compact size, anti-corrosive coating with smooth finish

Optional Accessories:

- Inside Manual Turntable

- Track with work car & mounted turntable.

- Motorized Turntable

- Tumble Basket for Batch blasting

- Any other special custom feature.

Our Standard Models:

- SU-9182

- SU-12090

- PR-9182

- PR-12090

- WT-9182

- WT-12090